Estimated reading time: 13 minutes

Key Takeaways

- Choose local 3D printing for ultra-fast turnaround, in-person DFM collaboration, and zero shipping costs.

- Online platforms excel at volume discounts, specialty materials, and consistent, network-level quality assurance.

- Always compare at least two local and two online quotes to balance cost, speed, and quality for each project.

- Use a weighted decision matrix (Cost 30 %, Speed 30 %, Quality 40 %) to reveal the best option objectively.

- Protect IP with NDAs, clarify hidden fees, and verify tolerance and finishing capabilities before committing.

TL;DR Verdict

If your timeline is screaming and you need hands-on DFM help, choose local vs online 3d printing. Especially if zero shipping, in-person inspection, and quick iteration will save your launch.

If you need volume pricing, specialty materials, or predictable platform-level QA, online usually wins. Still, compare both. Get two quotes and stack them side by side. The “best 3d printing service near me” sometimes beats a platform by days, even if it costs a little more.

Table of Contents

I’ve had to make the local vs online 3d printing call more times than I can count. Every time, the stakes felt real: budget, deadlines, and whether that part would actually snap into place. The choice determines if you hit your ship date or slip it. It shapes tolerance risk, finishing options, and how quickly you can iterate.

Over the years, I built a checklist and a simple decision flow. In this guide, I’ll walk you through it. I’ll show how I compare quotes, rate quality, and pick the “best 3d printing service near me.” I’ll also give you a practical framework for an “online 3d printing service review” so you can evaluate platforms with confidence.

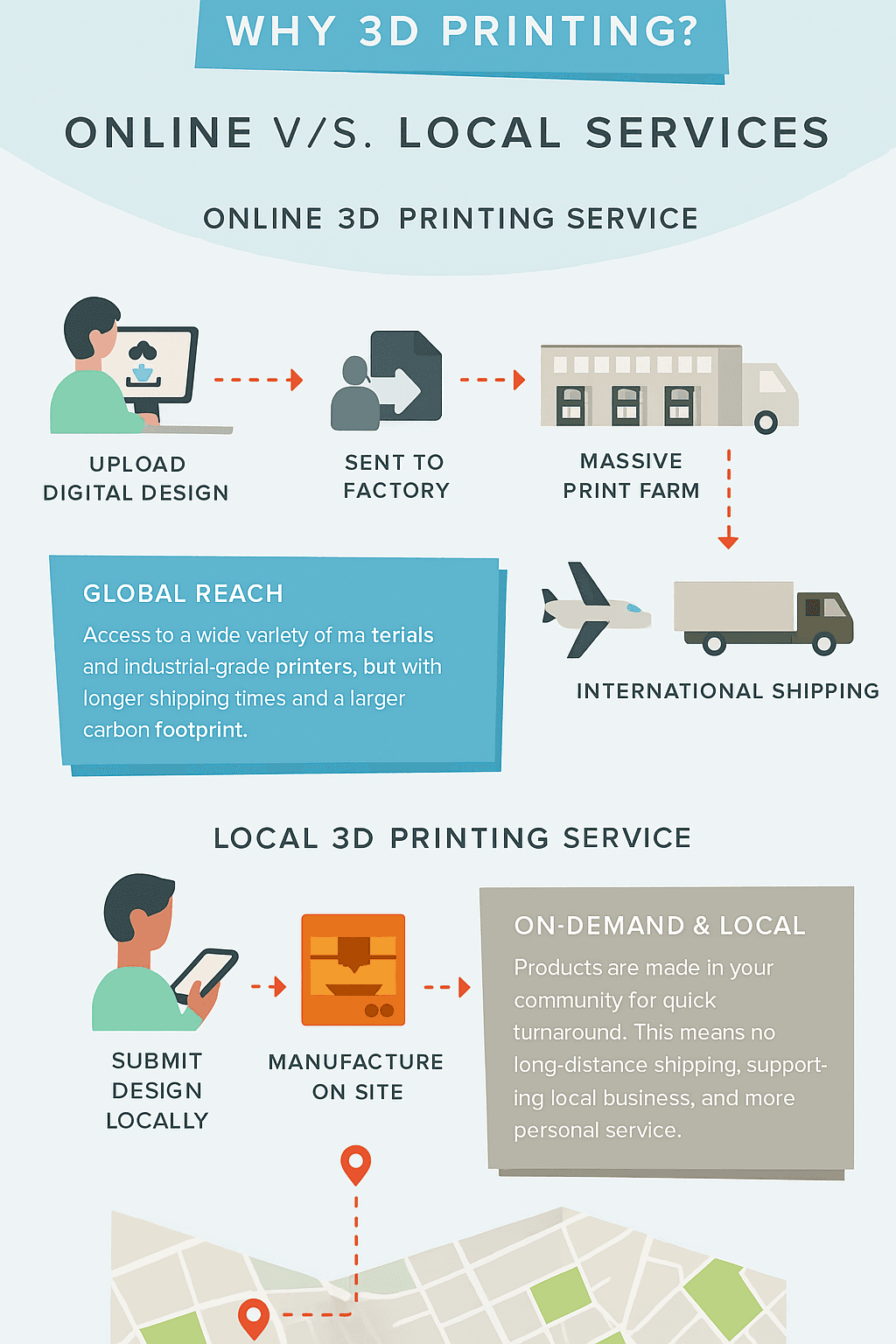

A quick note I’ve learned the hard way: local shops often mean no shipping fees and the chance for same-day or next-day pickup (source). Online platforms shine with instant quoting and a massive selection of materials and processes (source). That shapes almost every decision you’ll make.

Local 3D Printing vs Online — Pros and Cons

I’ve run this comparison on big and small projects. Here’s what I evaluate first.

Cost

- Local:

- Online:

Speed

- Local:

- Same-day or next-day is possible. I’ve literally walked in, adjusted a design, and picked up parts the next morning (source).

- You’re limited by shop hours and their queue.

- Online:

- Lead times are predictable. You’ll see expedited options, but shipping days still apply. Peak season can add delays.

Quality

- Local:

- You get human eyes and hands on your part. You can discuss layer orientation, supports, and post-processing in person.

- They can do bespoke tuning. I’ve had a tech tweak temperature and flow to nail a tricky overhang.

- Online:

- Standardized QA across a network brings consistency. Perfect for repeat batches.

- They usually have formal reprint or refund policies. That reduces risk.

Capabilities and Materials

- Local: Machine variety can be limited. But the best shops are wizards with custom tuning, tricky supports, and manual post-processing.

- Online: Huge tech stack: FDM, SLA/DLP, SLS, MJF, and metals. They also offer exotic materials and finishes. You can match the process to your use case with confidence (source).

Communication and Support

- Local: Face-to-face DFM is priceless. You can hold a failed sample and improve it together.

- Online: Ticketing systems, structured pre-print checks, and documentation are solid. Access to the operator isn’t as direct, though.

Risk and Accountability

- Local: If something is off, you walk in and they reprint. That’s low friction.

- Online: You rely on formal policies. Good platforms handle issues quickly, but shipping damage is a real risk.

IP and Security

- Local: Sign an NDA with the shop. Ask how they handle file storage and access. The USPTO has practical guidance on protecting design files and contracts for additive manufacturing (source).

- Online: Platform-level NDAs and access controls are common. Review data retention policies and how they use your files (source).

Sustainability

- Local: Fewer shipping emissions and easy pickup.

- Online: Efficient batching and consolidated logistics reduce per-part impact.

Bottom line: the local 3d printing vs online trade-offs hinge on urgency, volume, and material complexity. That’s why I always do a two-quote pass.

Cost Breakdown with Real-World Scenarios

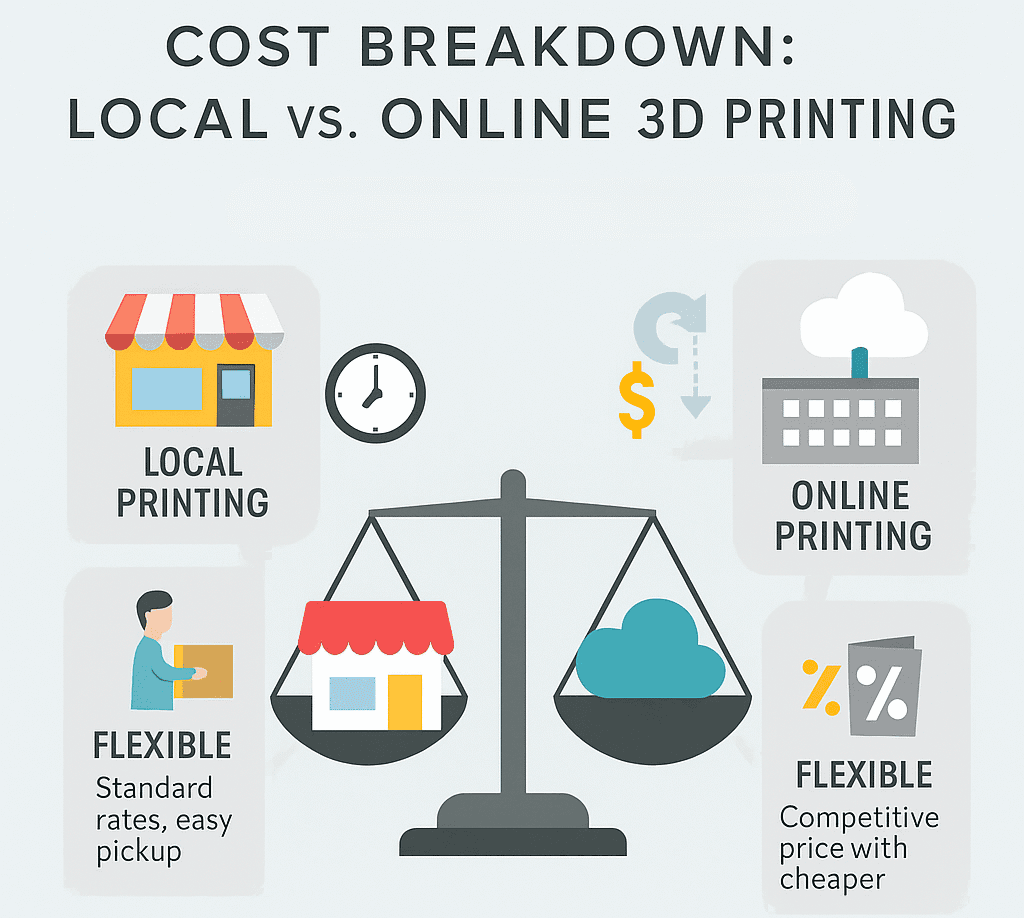

I track total landed cost. That means print price, finishing, shipping or pickup, and any rush fees. Here’s how local vs online 3d printing stacks up in practice.

Scenario A: Single Prototype

- Need it under 48 hours:

- Local: Same-day/next-day is realistic. You might pay a rush fee, but you save shipping and get in-person DFM.

- Online: You’ll pay for expedited printing plus overnight shipping. If you miss the cutoff, you’re toast.

- Flexible one-week timeline:

- Local: Standard rates and pickup. Easy.

- Online: Standard lead time and cheaper shipping. You might find promo codes for new users (source).

My rule: for a single urgent part, local vs online 3d printing almost always favors local. With a week or more, I compare both. Sometimes online wins with discounts.

Scenario B: Small Batch vs Larger Batch

- Small batch (10–50 units):

- Local: Per-unit cost can drop a bit, but local capacity may limit consistent quality across a batch.

- Online: Volume discounts unlock. You also get consistent QA across the run.

- Larger batch (100+ units):

- Local: Capacity and machine variety may be the ceiling.

- Online: This is their field. They’ll optimize your parts across machines, materials, and sites for price and speed.

Hidden Costs to Watch

- Support removal fees, especially for SLA/DLP.

- Specialty finishing: vapor smoothing, dyeing, painting.

- Tight tolerance guarantees and inspection reports.

- Reprint policies and who pays shipping on issues.

- Sales tax and courier surcharges.

I’ve been burned by “free reprint” that ignored express shipping. Always ask. The Prusa KB has a great reminder to compare apples to apples when assessing price structures (source).

Speed and Workflow Comparison of Local vs

Online 3D printing

Speed is more than “days to delivery.” It’s the iteration loop. That’s where local vs online 3d printing diverges.

Quote-to-Print Timeline

- Local: You can walk in with a USB or email a file and get a human quote. If they have an open machine, printing starts today.

- Online: Upload your file. The system runs manufacturability checks, suggests materials, and shows instant pricing. You schedule, then wait for shipping.

Iteration Loop Time

- Local: I’ve done same-day iteration—tweak, reprint, inspect, repeat—especially when using parametric design in Fusion 360 where a single parameter tweak drives the whole geometry.

- Online: Each loop includes upload, check, schedule, print, and transit. That adds days. However, for stable designs, online is fine.

Cutoffs and Holidays

- Local: Shop hours matter. Ask about weekend availability and holiday closures.

- Online: Expedited options exist, but carriers still have cutoff times and holiday slowdowns.

For rapid cycles, local vs online 3d printing favors local. For planned schedules, online’s predictability wins.

Quality, Tolerances, and Finishing

Let’s talk numbers. These are typical, not promises. Always confirm with your provider.

- FDM: ±0.2 mm or ±0.2%, whichever is greater.

- SLA/DLP: ±0.05–0.1 mm. Great for detailed prototypes.

- SLS/MJF (nylon): ±0.2 mm plus a small percentage of length.

- DMLS/SLM (metal): ±0.1–0.2 mm with post-machining for critical features.

If you’re fuzzy on how layer height and XY accuracy really affect surface quality, our 3D printer resolution guide breaks it down.

Ask both local and online providers for a tolerance coupon or sample print. It’s an easy way to verify capability before a full run.

Surface finish matters. Layer lines show based on orientation. I specify:

- Critical faces and preferred orientation.

- Thread standards and whether I want helical inserts.

- Post-processing: vapor smoothing for ABS, dyeing for nylon, painting, polishing, or bead blasting.

Quality is where local vs online 3d printing can look closer than you expect. A skilled local operator can outperform an average platform vendor on a complex geometry. But for repeatability and documentation, online platforms usually have the edge.

If you want a deeper dive into additive processes and their trade-offs, I like this overview by NIST: Additive manufacturing resources.

How to Find the Best 3D Printing Service Near Me

I keep a running shortlist. Here’s how I build it fast.

Search Strategies

- Google Maps: “3D printing service,” “rapid prototyping,” or “additive manufacturing.”

- Maker spaces and community labs. Great for prototypes and budget runs.

- Local 3D print bureaus and service bureaus.

- University lab listings. Students often run service programs.

Capability Vetting

- Ask for the machine list, materials, and build volumes.

- Request photos of portfolio samples similar to your part.

- Confirm finishing services: sanding, painting, inserts, vapor smoothing.

Key Questions to Ask

- What’s your turnaround guarantee?

- Do you provide QA checks or inspection reports?

- What’s your reprint or refund policy?

- Can we sign an NDA? How do you store files? The USPTO has solid guidance on NDAs and digital file protection for 3D printing (source).

On-Site Visit Checklist

- Look at calibration prints and test coupons.

- Inspect sample parts for layer consistency and surface finish.

- Note communication style and shop cleanliness.

- Ask to see how they package parts for pickup.

Getting Comparable Quotes

Send the same CAD files and units.

- Include tolerances, quantities, deadlines, and finish requirements.

- Specify critical features and preferred orientation.

This makes it easy to compare the best 3d printing service near me with a few clicks.

Online 3D Printing Service Review — What to Look For

I use a simple rubric for platforms. I score each category from 1–5.

Evaluation Rubric

- Price transparency: No hidden fees or surprise surcharges.

- Lead time accuracy: Quoted vs actual delivery times.

- Materials and process range: FDM, SLA/DLP, SLS, MJF, metals.

- QA documentation: Any inspection reports or certificates?

- Support responsiveness: How fast and how helpful?

The instant quoting and broad material selection are huge advantages online (source). MatterHackers also stresses checking fees and quoting accuracy upfront (source). For a full walkthrough, see our step-by-step guide to using an online 3D printing service.

How to Read User Reviews

- Filter by your material and process.

- Look at part complexity and size similar to yours.

- Separate prototype vs end-use part reviews.

- Note how issues were resolved. That’s revealing.

Mini Review Template

- Part type and use case:

- Material and process:

- Quoted price and lead time vs actual:

- Dimensional accuracy and tolerance:

- Surface finish quality:

- Issue resolution speed and satisfaction:

I apply this template across platforms for a consistent online 3d printing service review.

Use-Case Playbook — When to Choose Local vs Online 3d Printing

This is the cheat sheet pinned above my desk. It has saved me a dozen times on local vs online 3d printing decisions.

Choose Local If

- You need parts in under 48 hours.

- You want tight, high-touch DFM collaboration.

- Your assembly has critical fits that benefit from hands-on iteration.

- You prefer strict IP control with a single trusted shop.

Choose Online If

- You need specialty materials or processes.

- You require large, consistent batches with documentation.

- You need metal printing or multi-site delivery.

- You have a strict budget and can leverage volume discounts and promos.

Decision Tool

I use a simple scoring matrix for local vs online 3d printing. Weight each category:

- Cost: 30%

- Speed: 30%

- Quality: 40%

Score local and online from 1–10 in each category. Multiply by weights, add them up, and you’ll get a clear winner.

Example:

– Local: Cost 7, Speed 9, Quality 8 → Score = 0.3*7 + 0.3*9 + 0.4*8 = 7.9

– Online: Cost 8, Speed 7, Quality 9 → Score = 0.3*8 + 0.3*7 + 0.4*9 = 8.2

– Result: Online edges out for this case.

Checklist for quote requests (copy/paste and reuse):

- Files: STEP + STL

- Quantities: prototype and production

- Tolerances: global and critical features

- Materials: primary + backups

- Finish: orientation, supports, post-processing

- Deadline: hard date and “nice to have”

- Shipping or pickup preferences

- NDA/IP notes

Use this with every local vs online 3d printing request.

Common Pitfalls and How to Avoid Them

- Low-resolution STL exports. Re-export with finer chord height.

- Missing tolerance info. State global and critical tolerances explicitly.

- Unclear part orientation. Call out critical faces and strength directions.

- Under-specifying finishing needs. Include surface finish targets.

- Ignoring post-processing time. Paint, inserts, and smoothing add days.

- Forgetting shipping time or shop hours. Mark cutoffs on your calendar.

I’ve made every one of these mistakes. Now I keep a pre-flight checklist. It cuts iteration by half.

Conclusion and Next Steps

Here’s my honest take after years of trial and error. Local vs online 3d printing isn’t a one-time choice. It’s a per-project decision shaped by cost, speed, and quality needs. Local crushes urgent timelines, tight DFM loops, and in-person inspections. Online dominates volume pricing, specialty materials, and platform-level QA.

Do this now:

- Shortlist two local shops and two platforms.

- Use my decision tool and checklist to request apples-to-apples quotes.

- Run a cost–speed–quality comparison. Then pick the winner for your part.

If you’re still unsure, start with a single test part. That small experiment will clarify your path and make your next local vs online 3d printing decision effortless. And if you need help vetting the best 3d printing service near me or writing your own online 3d printing service review, borrow my templates above and run with them.

References and further reading:

– Local vs online cost and decision factors by Prusa Research (source)

– How to vet 3D printing services, quoting tips, and promos by MatterHackers (source)

– Same-day/local advantages and online platform range and quoting (source)

– IP protection and NDA guidance from USPTO (source)

FAQs

Q: Is local cheaper than online?

A: It depends. For a single part with pickup, local can be cheaper because there’s no shipping and you can avoid reprints via in-person DFM. Online often wins on volume discounts and specialty materials. Always compare local vs online 3d printing for your exact part and quantity (source).

Q: What’s the fastest option for my prototype?

A: Usually local. Same-day or next-day is realistic if the shop has capacity. Online has expedited options, but shipping adds days, especially around holidays (source).

Q: How do I protect my design files?

A: Use NDAs with local shops and review their file storage practices. For online platforms, read the NDA/terms and data retention policy. The USPTO’s guidance on 3D printing and IP is excellent (source).

Q: Which processes are best for prototypes vs end-use parts?

A: For quick prototypes, FDM is budget-friendly. For high detail, choose SLA/DLP. For tough end-use parts, SLS/MJF nylon is a favorite. For metal strength, DMLS/SLM with post-machining wins. Match these to your local vs online 3d printing options and deadlines.