Estimated reading time: 12 minutes

Key Takeaways

- Define detailed requirements (function, environment, quantity, materials, tolerance, finish, lead time) before requesting any quotes.

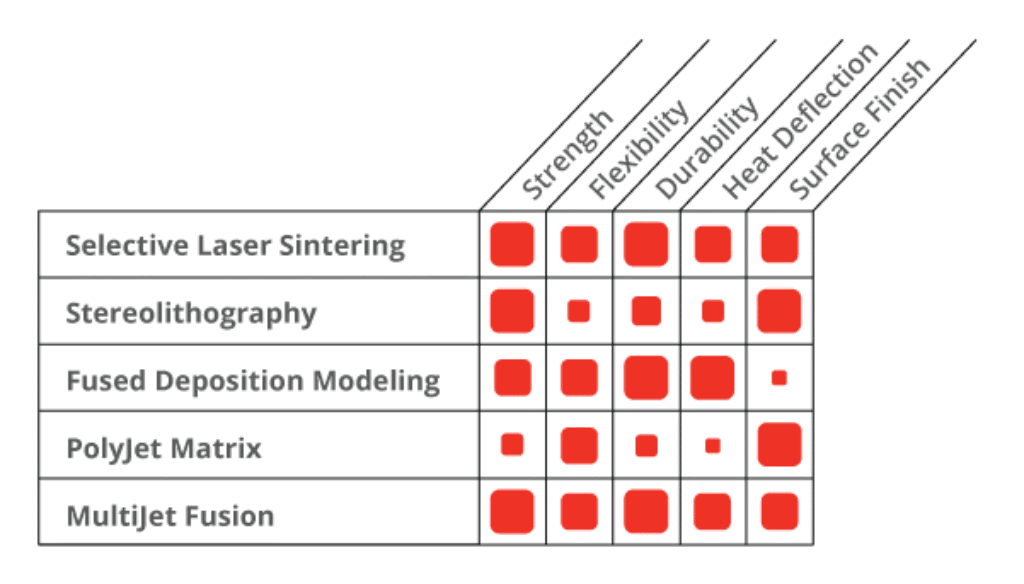

- Match your specs to the most suitable 3D-printing technology (FDM, SLA, SLS, MJF/SAF, DMLS/SLM, PolyJet) and material to avoid costly rework.

- Evaluate providers on capability, quality systems, pricing transparency, DFM support, IP security, logistics, sustainability, and reputation.

- Standardize variables and run pilot parts to compare quotes accurately and uncover hidden costs or quality issues.

- Watch for red flags such as vague build parameters, missing QC data, or hidden fees, and always maintain a qualified backup supplier.

Table of Contents

If you’ve ever Googled how to choose 3D printing service and felt overwhelmed, you’re not alone. I’ve been there—sifting through glossy photos, hidden fees, and tech jargon—so I built this 3D printing service guide to cut through the noise and help you make a confident choice fast.

When I first started outsourcing prints, I learned the hard way that success starts before you even get a quote. You have to define your requirements—materials, technologies, quantities, and tolerances—before you evaluate providers, or you’ll chase your tail and overspend (source). Also, reputation matters more than we admit. In fact, 84% of buyers trust third-party reviews as much as personal referrals, so I now treat provider reviews like gold (source). Stick with me and I’ll give you a step-by-step roadmap on how to choose 3d printing service aligned to your budget, timeline, and quality goals. Consider this your hands-on 3d printing service guide.

Quick-Start Decision Checklist

Before contacting any provider, I answer these core questions. They shave days off back-and-forth emails and lead to better quotes. Use this for online printing service selection and when selecting 3D printing service across multiple vendors.

- What’s the part’s function and mechanical requirements? Load-bearing? Cosmetic?

- What environments apply? Heat, cold, UV, moisture, chemicals?

- Quantity: proof-of-concept prototype, small batch, or production?

- Materials: plastics (PA12, ABS, PETG), resins, metals (Al, SS, Ti), or specialty?

- Dimensional tolerance and surface finish: e.g., ±0.1 mm, Ra < 2 µm?

- Budget: target cost per part and total project ceiling.

- Lead time and rush needs. Can you live with partial shipments?

- Post-processing: dyeing, vapor smoothing, heat treat, machining, painting?

I also keep a comparison spreadsheet. It has columns for material, process, tolerance, finish, lead time, price, risk notes, and revision history. If you want my template, grab the downloadable comparison spreadsheet mentioned later.

How to Choose 3D Printing Service: Match Needs to Technologies

This is the heart of how to choose 3D printing service: map your part’s requirements to the right printing technology. I learned this after burning weeks on beautiful but brittle SLA parts for a functional prototype. Wrong process. Right lesson.

Here’s a quick guide I use when shortlisting providers in my 3d printing service guide.

FDM/FFF (Fused Deposition Modeling)

- Layer height: 0.1–0.3 mm. Typical tolerance around ±0.2 mm.

- Strength along layers can be weaker; great for rough, functional prototypes.

- Budget-friendly and accessible. In 2020, FDM held about 46% market share, so you’ll find lots of capacity and options (source).

When to use: quick design validation, brackets, enclosures where finish isn’t critical.

SLA/DLP (Stereolithography/Digital Light Processing)

- Layer thickness: 25–100 µm.

- Very smooth surfaces (Ra < 1 µm with finishing).

- Tons of resin choices: rigid, tough, clear, high-temp.

When to use: high-detail prototypes, visual models, molds for casting, microfluidics. Not ideal for heavy mechanical abuse unless you spec the right resin.

SLS (Selective Laser Sintering)

- Uses nylon powder (often PA12). No support structures needed.

- Typical tolerance around ±0.3 mm.

- Excellent for complex geometries, snap fits, and functional parts.

When to use: lightweight functional parts, enclosures, grips. Great for batch runs where you want durability and design freedom.

MJF/SAF (Multi Jet Fusion/Selective Absorption Fusion)

- High throughput. Fine features and consistent mechanics.

- Excellent for mid-volume runs with good per-part economics.

When to use: production-like prototypes and small series where uniformity matters.

DMLS/SLM (Metal Printing)

- Metals like aluminum, stainless steel, and titanium.

- Typical tolerance around ±0.2 mm (post-processing often needed).

- Heat treatment and machining may be required.

When to use: complex metal parts, consolidated assemblies, or parts that are impractical to machine traditionally.

PolyJet

- Multi-material and full-color options.

- Great for thin walls and elastomer-like blends. Lower strength overall.

When to use: tactile prototypes, overmold simulations, color-accurate displays.

Materials and Finishing

- Polymers: ABS, PLA, PETG, nylon (PA11/PA12), TPU for flexible parts.

- Resins: standard, tough, flexible, high-temp, biocompatible (provider dependent).

- Metals: Al, SS, Ti, Inconel (availability varies).

- Ceramics and specialty resins exist for niche needs.

- Finish options: vapor smoothing, dyeing, painting, plating, anodizing, machining.

When you match process + material + finish to your requirement spec, you’re already 70% of the way through how to choose 3d printing service wisely.

Core Evaluation Criteria (3D printing service guide)

After you narrow down the right tech, evaluate providers systematically. Early on, I mixed apples and oranges and got confused. Now I run through this checklist to make apples-to-apples decisions for online printing service selection.

Capability Fit

- Technologies on offer: Do they run FDM, SLA, SLS, MJF/SAF, DMLS/SLM, PolyJet?

- Max build volume and machine count: Can they handle your part size and schedule?

- Material breadth: Does their PA12 meet your spec? Which resin families? Which alloys?

- Post-processing: dyeing, vapor smoothing, CNC machining, heat treatment, painting. One-stop shops reduce handoffs.

Quality Assurance

- ISO 9001 certification: Look for documented processes and continuous improvement. See the ISO 9001 quality management standards.

- Process standards: Do they align with ASTM additive manufacturing standards?

- Metrology: Do they follow NIST additive manufacturing metrology guidance for precision and inspection?

- Inspection: Can they provide CMM reports, surface roughness data, and Certificates of Conformity?

- Certifications: AS9100 for aerospace, ISO 13485 for medical.

- Repeatability: Ask for historical capability. Desktop FFF can repeat at ±0.1 mm in many setups, which hints at what’s possible with dialed-in systems and good support/warranty coverage (source).

A great provider will happily send a sample coupon with inspection notes. If they dodge QC questions, I move on.

Pricing Model

- Part-based vs volume-based pricing: Which tiers unlock discounts?

- Setup fees, minimum orders, post-processing, shipping, and taxes.

- Quote comparability: Same orientation, same finish, same quantity. If not, you’re not comparing the same thing.

Tip: Build orientation can swing price and finish quality. Lock it in.

Lead Time & Reliability

- Ask for their on-time delivery rate and typical queue time.

- Check rush fees and cutoffs. Do they offer partial shipments?

- Do they disclose machine downtime contingencies?

DFM Support & Customer Service

Engineering support is becoming a superpower. 60% of companies plan to increase engineering and R&D outsourcing, so in-house provider support is a time-saver (source).

- DFM consults: Can you hop on a call to optimize wall thickness or anisotropy?

- Tolerance advice: Will they flag unrealistic specs early?

- Responsiveness: Email reply times, portal chat, after-hours support.

File Handling & IP Security

- NDAs, encrypted uploads, data retention limits.

- ITAR/EAR understanding for export-controlled projects.

- Clear policy on deletion upon request.

Platform UX (online printing service selection)

- Instant quoting accuracy and transparency on base price vs add-ons.

- On-platform model repair, wall thickness checks, and orientation tools.

- Rich material libraries, spec sheets, and design guides.

- Order tracking dashboards and milestone notifications.

Logistics

- Location and shipping carriers. Ground vs air options.

- Customs prep for international shipments and HS codes.

- Packaging standards for delicate parts.

Sustainability & Traceability

- Powder refresh rates and recycled media usage.

- Material lot traceability and certificates.

- Sustainable packaging options.

Policies & Reputation

- Reprint/return policies and warranties.

- Case studies and years in business.

- Third-party reviews you can verify—remember, 84% of buyers trust them (source).

If you’re still asking how to choose 3d printing service at this stage, the answer is: pick the provider that checks these boxes and communicates like a partner, not a vendor.

How to Compare Quotes (selecting 3D printing service)

Here’s my battle-tested approach for selecting 3d printing service without overpaying or compromising quality.

- Standardize variables

- Fix orientation, tolerance spec, finish level, and quantity before quoting. This removes 80% of confusion and helps you nail how to choose 3d printing service with clarity.

- Request a sample coupon or benchmark part

- A small L-bracket or tensile coupon works. Evaluate surface finish, hole accuracy, and text legibility side-by-side.

- Build a comparison table

- Add columns for cost per part, total price, lead time, measured accuracy, surface roughness (Ra), and risk notes (e.g., “porosity near overhangs”).

- Calculate total cost of ownership

- Include post-processing, shipping, packaging, customs, rework, scrap rate, and admin time. The cheapest quote often grows fangs later.

- Example walkthrough

- Prototype hinge: I once tested a living-hinge design. SLA looked beautiful but cracked during fatigue tests. SLS PA12 survived cycles, and MJF gave the best uniformity at a slightly higher price. SLS was fastest; MJF had the best surface without extra finishing.

- Low-volume end-use bracket: We needed 200 brackets with modest load. FDM was cheapest but required support cleanup, adding labor. MJF delivered consistent parts, tighter dimensional control, and faster batch processing. When I ran the numbers, MJF’s higher per-part cost was offset by zero rework. That’s how to choose 3d printing service with production realities in mind.

Special Scenarios

Different contexts tweak the priorities in your online printing service selection.

- Rapid prototyping vs end-use production

For prototypes, speed and cost trump durability. I lean toward FDM or SLA. For end-use, I validate material properties, isotropy, and post-process needs, often SLS, MJF, or metals—especially if I’m exploring 3D printing for mass production. - Regulated industries (medical, aerospace)

Demand full traceability, material certs, and documented process controls. Ask for AS9100/ISO 13485 and lab reports. This is crucial when deciding how to choose 3d printing service safely. - Large-format parts and assemblies

Check build volume limits. Consider splitting parts into sub-assemblies with mechanical fasteners or dovetail joints. A smart assembly plan can cut build failures. - Budget-conscious hobbyist vs enterprise procurement

Hobbyists: pick FDM or basic SLA, batch orders to reduce shipping. Enterprises: negotiate pricing tiers, minimum order quantities, and service-level agreements.

Risk Mitigation & Supplier Qualification

I sleep better when I reduce unknowns. Here’s my approach for selecting 3D printing service with fewer surprises.

- Pilot runs

Define acceptance criteria: key dimensions, tensile strength, fatigue cycles, or pressure tests. Approve only if data meets spec. - Quality agreements

Draft inspection plans, sampling rates, and documentation requirements. Use PPAP or First Article Inspection for regulated contexts. - Backup suppliers

Qualify at least one alternative. You’ll thank yourself when a primary supplier’s queue is jammed.

Red Flags to Avoid

These are my no-go signs when I’m evaluating how to choose 3d printing service.

- Vague build parameters or “trust us” answers about orientation and layer height.

- No QC data or Certificate of Conformity with samples.

- Quotes that swing wildly or hide setup, finishing, or shipping fees.

- Slow or inconsistent communication.

- No clear policy on failed builds, reprints, or refunds.

One time, a provider refused to disclose orientation choices “for proprietary reasons.” The parts warped exactly where I feared. Lesson learned.

Glossary (3D printing service guide)

- DFM (Design for Manufacturability): Design rules that make parts easier and more reliable to produce.

- Isotropy: Uniform material properties in all directions. Critical for load-bearing parts.

- Layer height: Thickness of each printed layer; smaller equals finer detail but longer print times.

- Tolerance: Allowed dimensional deviation, like ±0.1 mm.

- Ra (surface roughness): Average roughness height in micrometers. Lower is smoother.

Conclusion & Next Steps

Let’s recap the framework for selecting 3D printing service:

- Define your requirements first: function, environment, quantity, materials, tolerance, finish, and lead time.

- Map needs to technology: FDM, SLA, SLS, MJF/SAF, DMLS/SLM, or PolyJet.

- Evaluate providers on capability, quality systems, pricing model, DFM support, IP security, platform UX, logistics, sustainability, and reputation.

- Compare standardized quotes, run pilot tests, and lock in quality agreements.

- Maintain a backup supplier and watch for red flags.

I’ve packaged my decision checklist and quote comparison template for you. Download them, use them, and start your online printing service selection with a small test order this week. It’s the safest way to validate and build momentum.

If you came here wondering how to choose 3D printing service, you now have a practical playbook. Save this 3D printing service guide, share it with your team, and keep iterating. The right partner is out there—and with this process, you’ll find them faster.

Downloadable Asset

- Decision flowchart: Requirements → Recommended technologies → Provider questions.

- Quote comparison template: Excel Sheet with cost, lead time, orientation, finish, risk, and QA fields.

Final pro tip: The more clearly you communicate your specs, the better your parts and the fewer surprises. That’s the secret sauce behind how to choose 3D printing service with confidence—every single time.

Frequently Asked Questions

Q: What information should I gather before requesting a 3D-printing quote?

A: Define the part’s function, environment, quantity, material, tolerance, surface finish, budget, lead time, and any post-processing needs.

Q: How do I match my part to the right 3D-printing technology?

A: Compare your mechanical, cosmetic, and volume requirements with each process’s strengths—e.g., FDM for budget prototypes, SLA for high detail, SLS or MJF for durable functional parts, and DMLS for complex metal components.

Q: What quality certifications should a professional provider have?

A: Look for ISO 9001 as a baseline, plus AS9100 for aerospace or ISO 13485 for medical, along with adherence to ASTM and NIST additive manufacturing standards.

Q: How can I accurately compare quotes from different vendors?

A: Standardize orientation, tolerance, finish, and quantity across all quotes, request sample coupons, and build a comparison table that includes total cost of ownership.

Q: What are common red flags when choosing a 3D-printing service?

A: Vague build parameters, missing QC data, hidden fees, poor communication, and unclear reprint or refund policies signal you should look elsewhere.