Estimated reading time: 15 minutes

Key Takeaways

- Picking the best 3D printing service goes beyond price—evaluate speed, precision, material range, IP security, and scalability to bridge production.

- Lead-time tiers, tolerance capabilities, and post-processing options differ by process (SLA, SLS, MJF, DMLS) and provider, so align them with your project stage.

- Professional prototyping services should provide transparent pricing, robust QC documentation, automated and human DFM support, and NDA-backed data security.

- Global instant-quote networks shine for rapid turnaround, while vertically integrated or specialty shops excel at precision, advanced materials, and compliance.

- Using a structured comparison framework and starting with small validation orders de-risks schedules and accelerates iteration to production.

If you’re racing a deadline, the best 3D printing service prototypes can feel like a cheat code. The right partner helps me iterate in days, slash design risk, and reach that “ship it” moment faster. I’ve learned the hard way that picking the best 3D printing service prototypes isn’t about a logo or price alone—it’s about speed, precision, materials, and the business features that keep your IP safe and your team in sync.

When I say professional prototyping service, I mean a provider with industrial-grade equipment (SLA, SLS, MJF, DMLS), tight QC, and real engineering support. They offer DFM feedback, transparent quotes, NDAs, ISO certifications, and a secure portal—not just a desktop printer and a hopeful attitude.

Here’s the evaluation framework I now use routinely: lead time speed (standard vs expedite), precision and QC (tolerances, inspection), material and process breadth, post-processing and finishing options, DFM support (automated and human), IP/security and compliance, pricing transparency, and scalability into bridge production. Many top services advertise next-day turnaround for plastics, including Protolabs and Fictiv, and it’s legit under the right conditions. Realistic tolerances for additive tend to land around ±0.005–0.012 in, while CNC can hit ±0.001 in when needed.

What Makes the Best 3D Printing Service Prototypes for Product Teams

I keep a scorecard for every prototype order. It sounds nerdy. It works.

Speed

Lead time is king in early sprints. I plan around two tiers:

- Expedited: 24–48 hours for SLA/SLS/MJF if you catch the cutoff, with capacity-dependent batching.

- Standard: 3–7 business days for most plastics; metals can run longer.

Cutoff times matter more than we admit. I’ve missed 2 p.m. Pacific and lost two days. Larger networks with deeper machine pools are more likely to hit true next-day plastics, especially for common nylon and SLA resins (source).

From experience, the best 3D printing service prototypes offer an expedite button that actually means something. If a rush fee doesn’t move your ship date, that’s a red flag.

Precision & Quality

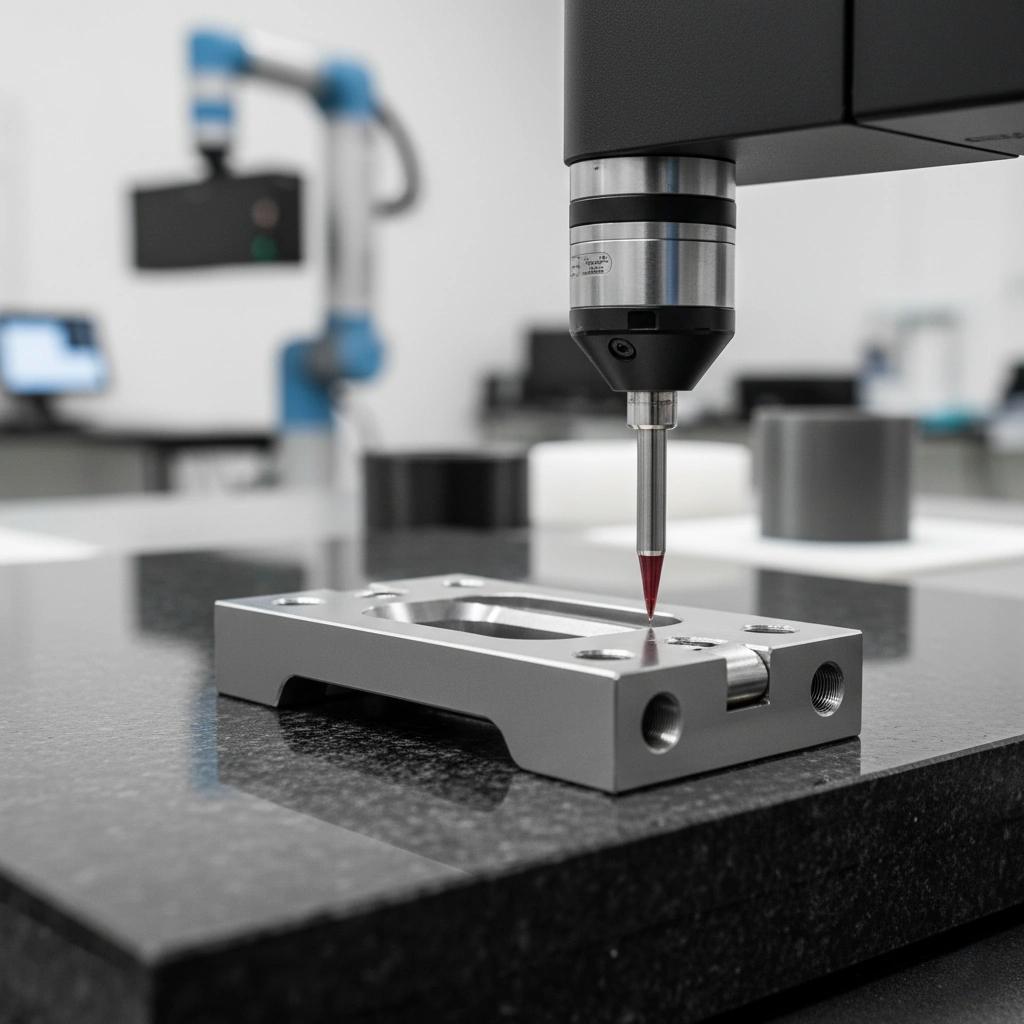

Tolerances are the silent killer of schedules. For additive, most providers quote ±0.005–0.012 in depending on process and part size, while CNC support inside the same network can hit ±0.001 in for critical features.

- Repeatability: Batch-to-batch consistency and machine calibration logs.

- Anisotropy: FDM is more anisotropic; SLS/MJF yield near-isotropic mechanicals.

- Surface finish: Typical Ra varies—SLA is smoothest, SLS/MJF are matte and slightly grainy.

- Inspection: CMM, laser scan, or CT options and what documentation I’ll receive.

On a recent hinge test rig, a provider sent a CMM report that saved me from a mismatch with a purchased bearing. That’s the quiet value of a professional prototyping service.

Materials & Processes

Breadth matters. It’s not just a deep resin list; it’s mechanical data and certifications.

- Plastics:

- SLA: Standard, tough, clear, high-temp, and biocompatible resins.

- MJF: Nylon 12/11 with strong isotropy and color-dye options.

- FDM: ABS, PC, Nylon, ULTEM/PEI for heat resistance.

- Elastomers: TPU/TPE for flexible parts.

- SLS: PA12/PA11, glass-filled options.

- Metals:

- DMLS/SLM: Aluminum, stainless steel, titanium; post heat treatments.

- Binder jet: Steel and multi-step sintering for cost-effective metal-like parts.

I match materials to the stress and environment of the test. High-temp PEI for under-hood clips, PA12 for robust jigs, clear SLA for fluidic checks, and Ti DMLS for lightweight structural prototypes.

Post-Processing & Finishing

When I need a part to look “production,” finishing is the bridge:

- Vapor smoothing (great for FDM surfaces and certain SLA resins).

- Dyeing (MJF/SLS) for consistent color.

- Bead blasting for uniform matte.

- Secondary machining for bores and interfaces.

- Heat-set inserts, tapped holes, painting, and texture mapping.

I once dyed an MJF housing black and applied a light bead blast; my marketing lead thought it was injection molded. That’s a win.

DFM & Engineering Support

Automated DFM is table stakes now. I look for systems that flag thin walls, overhang issues, trapped powder, and unsupported inserts before I pay. But the real magic is a quick engineer review. A 10-minute call with a process engineer has saved me days of “trial and error.”

Business Features & Security

I won’t upload a critical CAD without:

- NDAs and explicit IP protection.

- ISO 9001, and if medical, ISO 13485; ITAR for defense.

- Secure portal access, version control, and audit logs.

- Enterprise features: BOM/PO workflows, net terms, API/ERP integrations, real-time tracking.

Security-savvy buyers prioritize platforms with strong NDAs and locked-down portals, and so do I.

Pricing Transparency

I love instant quoting. It resets expectations across engineering and purchasing. I expect breakdowns by:

- Material/process and machine time.

- Volume and nesting efficiencies.

- Finish options and inspection tiers.

- Volume discounts or subscription/enterprise tiers.

Some networks display price sensitivity to orientation or layer height. That helps me design with cost in mind.

Scalability

The best 3d printing service prototypes don’t trap you at “one-offs.” They help you bridge to 50–1,000 units (and even explore 3D printing for mass production) with:

- Design locking and version traceability.

- Repeatable setups and QC plans.

- Pack-out, labeling, and light assembly.

Quick Primer – Processes for a Prototype 3D Printing Service

I keep a one-pager by my desk. It saves me from “wrong tool for the job” mistakes.

FDM (Fused Deposition Modeling)

- How it works: Thermoplastic extrusion layer by layer.

- Tolerances: Typically ±0.005–0.020 in depending on size.

- Surface: Visible layer lines; can be smoothed or machined.

- Strength: Strong in-plane, weaker across layers.

- Best for: Large, durable concept models and functional fixtures.

SLA (Stereolithography)

- How it works: UV laser cures photopolymer resin.

- Tolerances: ±0.002–0.005 in; very fine details.

- Surface: Smoothest among polymers; clear options.

- Properties: Stiff, sometimes brittle; biocompatible resins exist.

- Best for: Cosmetic housings, microfluidics, snap-fit trials with caution on brittleness.

SLS (Selective Laser Sintering)

- How it works: Laser sinters nylon powder.

- Tolerances: ±0.005–0.010 in.

- Surface: Slightly grainy; bead blast improves feel.

- Properties: Tough, near-isotropic; great for jigs and end-use samples.

- Best for: Functional prototypes, snap fits, living hinges, fixtures.

MJF (Multi Jet Fusion)

- How it works: Agents + IR fuse nylon powder.

- Tolerances: ±0.005–0.010 in, fine features.

- Surface: Uniform matte gray/black; dyes well.

- Properties: Strong, consistent; fast build cycles.

- Best for: Fast functional parts, small production batches, fine text and detail.

PolyJet

- How it works: Inkjet photopolymers, UV-cured.

- Tolerances: ±0.001–0.005 in; excellent detail.

- Surface: Very smooth; multi-color, multi-material.

- Best for: Appearance models, overmold simulations, ergonomic studies.

DMLS/SLM (Metal Powder Bed Fusion)

- How it works: Laser fuses metal powder.

- Tolerances: ±0.002–0.010 in; machining often used for critical features.

- Post: Heat treatment for stress relief; high density and mechanical strength.

- Best for: Metal prototyping of brackets, manifolds, heat exchangers, and tooling.

If you’re curious about standards and the science behind these processes, check out these NIST additive manufacturing resources. It’s a solid, non-commercial deep dive.

Shortlist of Top Professional Prototyping Service Providers

I keep a short roster to match different needs. Here’s how I frame it.

Global Instant-Quote Networks

Xometry, Hubs, Fictiv: Breadth of materials and global capacity. Typical 24–48 hr for common plastics with automated DFM, QC reports, portals, and APIs (source).

- Best for: Speed, variety, and multi-site resilience.

- Pricing: Transparent, dynamic; expedites available.

- Limitations: Less control over exact machine/site unless you upgrade service tiers.

Vertically Integrated Manufacturers

Protolabs, Materialise: Tight process control, robust QC, consistent SLAs, and engineer reviews. Protolabs is my go-to for time-critical SLA and MJF parts with clean documentation (source).

- Best for: High-trust timelines and precision.

- Pricing: Premium for the reliability and rigor.

- Limitations: Less flexible on edge-case materials without custom engagement.

Specialty Metals & Advanced Materials

3D Systems On Demand, GKN Additive: Deep metal expertise, heat treatments, aerospace/medical certs, and mechanical property guarantees.

- Best for: DMLS/SLM prototypes, aerospace brackets, medical implants.

- Pricing: Higher; think development-grade, not commodity.

Niche/Form-and-Finish Shops

Shapeways, Sculpteo, JawsTec: Great for aesthetic finishes, color options, and small batch runs. Shapeways has convenient workflows for color and texture on SLS/MJF (source).

- Best for: Design-forward projects, consumer product looks-like prototypes.

- Pricing: Competitive for finish-heavy one-offs; watch lead times for complex post-processing.

Every one of these is a professional prototyping service with varying strengths. The best 3d printing service prototypes shortlist is contextual—match the provider to the job.

Comparison Framework for a Professional Prototyping Service

I use this comparison grid in kickoff meetings:

- Lead Time Tiers:

- Expedite: 24–48 hours.

- Standard: 3–7 days plastics; 5–12 days metals.

- Tolerance Capabilities:

- FDM: ±0.005–0.020 in.

- SLA: ±0.002–0.005 in.

- SLS/MJF: ±0.005–0.010 in.

- CNC inside network: as tight as ±0.001 in.

- Material Library & Certs:

- Nylon (PA12/PA11), PC, ABS, ULTEM, TPU, clear/tough SLAs;

- Al/SS/Ti for metals;

- ISO 9001/13485 where required.

- DFM Review Type:

- Automated flags

- human engineer consultations.

- IP/Security:

- NDA

- secure portal

- ITAR options

- audit trails

- Order Management:

- Web portal

- API

- ERP integration

- BOM upload

- real-time tracking

- QC Documentation:

- Basic inspection

- CMM

- CT scanning

- material certs on request.

- Price Transparency:

- Instant quotes

- finish add-ons itemized

- expedite fee clarity.

his framework has consistently led me to the best 3d printing service prototypes for each phase.

How to Choose a Prototype 3D Printing Service (Decision Guide)

Stage-Based Decisioning

- Concept validation: Favor SLA or FDM for speed and cost.

- Functional testing: SLS/MJF for toughness and isotropy.

- EVT/DVT: Match tolerances and materials more tightly; consider inserts and machining.

- Pilot production: Choose a provider with repeatability, QC plans, and traceability.

Part-Driven Decisioning

- Size and geometry: Large parts favor FDM or split builds; fine features point to SLA/MJF.

- Tolerances: Critical bores may need post-machining.

- Loads and temperature: Nylon, PC, or ULTEM; metals for high strength-to-weight.

- Cosmetic finish: SLA for smoothness; MJF + dye + blast for consistent matte.

Risk & Compliance

Medical or aerospace? Ask early for ISO 13485, material certs, batch records, and validation protocols. Don’t assume—they exist, but they require setup.

Vendor Selection Checklist

- Must-haves:

- Lead time SLA with clear expedite rules.

- Tolerance capability aligned to your specs.

- DFM support beyond auto-flags.

- IP security and NDA.

- Nice-to-haves:

- Color, texture, engraving.

- Volume discounts, subscription pricing.

- API/ERP integration for scale.

Start with a small sample order, review documentation, and stress test support. That’s how I’ve found the best 3d printing service prototypes before committing big dollars.

Rapid Prototyping Online Workflow

This is the loop I run almost weekly when using an online 3D printing service.

CAD Prep

- Units and scale: Triple-check before export (see our model prep checklist).

- Wall thickness: Respect process minimums.

- Draft and fillets: Reduce stress risers and print artifacts.

- Threads: Call out ISO vs UN; consider heat-set inserts.

- Tolerance callouts: Define critical-to-quality features.

Upload & Instant Quote

- Formats: STEP for features, STL for meshes—our file format guide covers common pitfalls.

- Select process/material; preview cost and lead time.

- Use quote sliders to test orientation or finish impacts on price.

Automated DFM Flags

- Common hits: Thin walls, unsupported overhangs, trapped powder.

- Resolve yourself or request an engineer review inside the portal.

Engineer Reviews & Iterations

- Respond to markups, submit change requests, and re-quote fast.

- I keep a simple change log so decisions don’t vanish in Slack threads.

Approvals, Payment & Tracking

- Lock version, approve quote, set PO or payment.

- Track builds in real time, including inspection steps if available.

Receiving & Feedback Loop

- Inspect critical features first; run test fits.

- Share photos and metrology with the vendor to improve the next run.

- That’s rapid prototyping online in a nutshell—tight loops, real data.

Cost and Lead Time Expectations

I budget in ranges, then refine after the first quote.

- SLA: $30–$100 per part for small/medium, finish-dependent.

- SLS: $50–$150; nesting can lower per-part cost.

- MJF: $70–$200; fast for batches with dye/blast.

- DMLS metals: $200–$600+; plan on machining for critical surfaces.

Expedite fees: Expect 25–50% surcharge to jump the queue. For SLS/MJF, nesting multiple parts or variants reduces per-unit cost—handy for A/B feature tests. Total cost of iteration beats over-optimizing early; at scale or for tight tolerances, I sometimes switch to CNC or urethane casting to control cost and finish.

And yes, the best 3d printing service prototypes often pay for themselves by shaving weeks off schedules and catching design flaws sooner.

Case Snapshots (Practical Evidence)

- Hardware startup: We landed a functional MJF prototype in 72 hours with threaded heat-set inserts and a matte black dye. Two design spins later, the hinge met torque targets and the BOM was locked for EVT. That’s when I knew we’d chosen the best 3d printing service prototypes for that sprint.

- Medical device team: Clear SLA microfluidic housings with biocompatible resin and ISO 13485 documentation arrived on time. We ran leak tests the same day and validated the channel geometry for DVT. The professional prototyping service’s paperwork saved us weeks in QA sign-off.

- Automotive fixture: An SLS PA12 jig with metal inserts arrived with a dimensional report; the shop hit ±0.008 in across critical datums. The installer sent me a high-five emoji. That’s a rare day.

Advanced Tips for Production-Like Prototypes

- Orientation control: Specify it for both mechanical strength and visible surfaces.

- GD&T: Call out CTQs explicitly. Don’t let “nominal” hide the real needs.

- Post-processing: Vapor smoothing, paint, and texture can simulate molded feel.

- Metal hardware: Design for heat-set inserts or tapping; avoid forcing after print.

- Metrology: Ask for CMM or laser scans on pilot runs and compare to CAD. Build a feedback loop between design and quality.

These are the little things that make the best 3d printing service prototypes feel like factory parts.

Risks and Mitigations

- Warping and anisotropy: Add ribs, control orientation, and consider SLS/MJF for isotropy.

- SLA brittleness: Choose tough/impact resins; avoid sharp corners.

- Metal porosity/oxidation: Specify heat treatment and surface sealing as needed.

- Mis-specified tolerances: Define critical features and request inspection reports.

- IP exposure: Use NDAs, secure portals, and limit file access. A professional prototyping service should offer all of this by default.

I also print test coupons for tensile or heat tests. The data kills debate.

Conclusion and Next Steps

If you want the best 3D printing service prototypes, match your stage and part needs to a provider’s strengths. For pure speed, global networks win. For ultra-reliable precision, vertically integrated shops shine. For metals, go specialty. For form-and-finish, pick a niche shop.

My playbook is simple:

- Use the comparison framework above.

- Start with a small validation order to test speed, quality, and documentation.

- Lock your DFM loop, specify inspection, and secure your IP.

Follow that, and you’ll consistently land the best 3d printing service prototypes with fewer surprises and faster launches. And if you’re building a team checklist, base it on the professional prototyping service criteria we covered. It has saved my schedule more times than I can count.

Helpful references and provider overviews:

- Protolabs 3D printing capabilities and lead times (source)

- Fictiv’s rapid prototyping online platform and QC reporting (source)

- Shapeways for finishes and small batch runs (source)

- Turnaround claims, tolerance ranges, and evaluation criteria (source)

Frequently Asked Questions

Q: How do I choose between SLS and MJF for functional prototypes?

A: Both are powder-bed nylon processes with similar tolerances, but MJF generally offers faster build cycles and easier dyeing, while SLS has a broader material library. Pick the one that best matches lead time and material needs.

Q: What’s the most cost-effective way to iterate multiple design variants?

A: Nest variants in a single SLS or MJF build to reduce per-part cost, then leverage instant-quote sliders to see how orientation or layer height impacts pricing.

Q: Can I get production-like surface finish straight from the printer?

A: Not usually. Processes like vapor smoothing, bead blasting, dyeing, or paint are key to achieving injection-mold-like aesthetics from printed parts.

Q: Do professional prototyping services sign NDAs automatically?

A: Most reputable providers make NDAs available at upload or account creation, but always verify that secure portals, access controls, and audit logs back up the paperwork.

Q: How fast can a metal prototype be delivered?

A: Expedited DMLS/SLM parts can arrive in 5–7 business days, but lead time depends on alloy availability, heat treatments, and any required post-machining.