Estimated reading time: 10 minutes

Key Takeaways

- 3MF is preferred when supported because it preserves units, colors, materials, and assemblies in one compressed file.

- STL remains the universal fallback for monochrome, single-material parts and quick quotes.

- OBJ supports full-color and textured prints but requires packaging the OBJ, MTL, and textures correctly.

- STEP maintains exact CAD geometry for precision mechanical parts, though not every service accepts it.

- Double-check units, mesh integrity, and service guidelines before uploading to avoid scaling errors and delays.

Table of Contents

I used to think a file was just a file. Drag, drop, print, done. Then a client’s mini prototype arrived at 25.4 times larger than intended because my STL exported in inches, and their service assumed millimeters. Ouch. That was my wake-up call to get serious about 3d printing service file formats, and it changed how I prep every model.

The main 3d printing service file formats—STL, OBJ, 3MF, and STEP—differ in how they represent geometry, what metadata they keep, their compatibility with online services, and which printing scenarios they’re best suited for (source). Picking the right one isn’t busywork. It reduces upload errors, preserves units, materials, and colors, and can shave days off production—especially when you follow a proven online 3D printing service guide. In this guide, I’ll break down STL vs OBJ, the 3MF file format, and STEP, and help you make a quick, confident call on the best file format for 3D printing with online services.

Understanding 3D Printing Service File Formats: Mesh vs Solid Geometry

Before we dive into file types, let’s talk geometry.

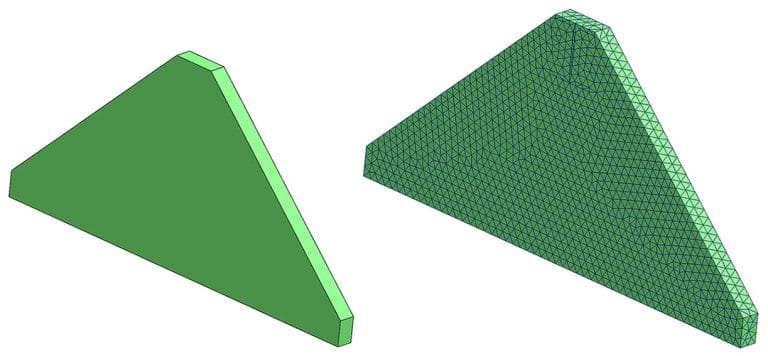

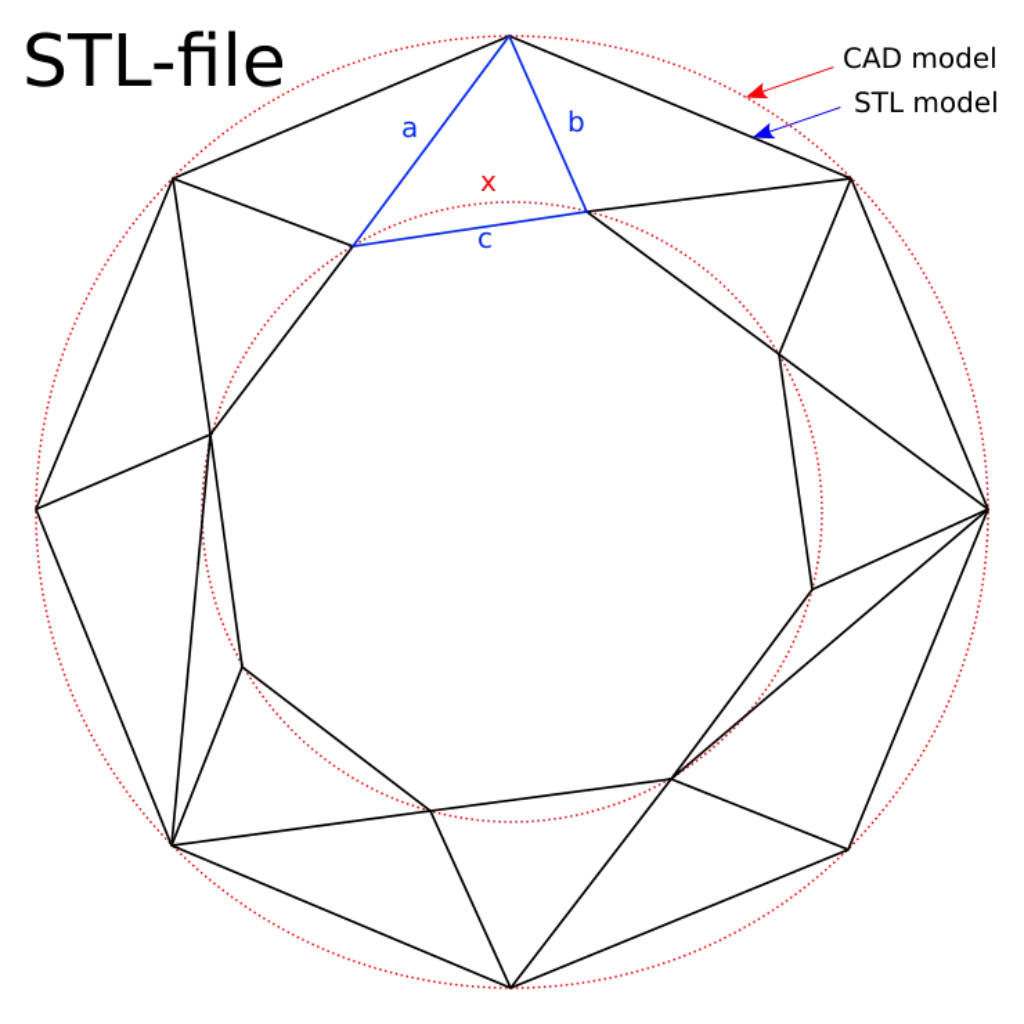

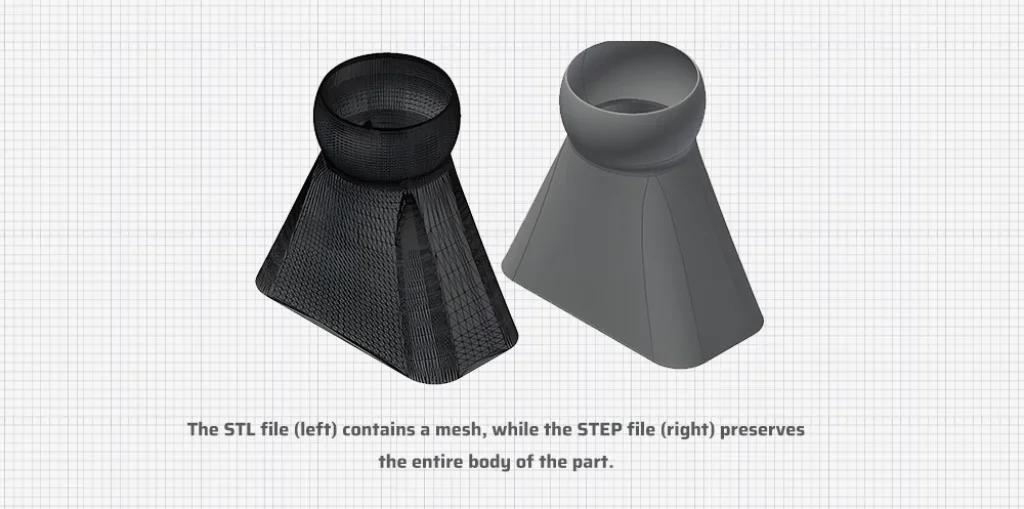

Mesh formats approximate shapes with lots of tiny facets. Think triangles stitched into a quilt. STL, OBJ, and 3MF fall into this camp. They’re fast to slice and widely supported. But they can introduce faceting if exported too coarsely, and they’re vulnerable to non-manifold errors that can break a print.

Solid/B-Rep formats store the exact math of your surfaces. STEP is the rock star here. It’s CAD-true. It preserves engineering tolerances and is perfect when parts must fit with zero guesswork. Services will tessellate STEP into a mesh for printing on their end. If you’re modeling in CAD—especially with parametric design in Fusion 360—exporting STEP keeps that precision intact.

When I’m prepping for online services, I keep these technical factors front and center:

- Units and scaling: mm vs inches gets people every week.

- Watertightness/manifoldness: the mesh must be closed. No cracks.

- Color/material/texture data: only some formats carry this.

- Assemblies and metadata: critical for multi-part jobs.

- File size and compression: large meshes can choke upload portals.

These fundamentals will shape how you use 3D printing service file formats across different jobs.

Format Deep Dives: Pros, Cons, Best-use Cases, and Export Tips

STL

Definition: STL is a mesh of triangles with no baked-in metadata like units, colors, or materials (source). It’s the OG of 3D printing.

Best for:

- Single-color, single-material parts.

- Default fallback when other formats aren’t supported.

- Quick quotes and simple prototypes—especially when the service does not handle color.

My take:

If I’m debating stl vs obj and there’s no color, STL usually wins for simplicity. It’s still the best file format for 3D printing when I need maximum compatibility and no surprises.

Export tips I actually use:

- Choose binary STL for smaller size.

- Set chord height 0.01–0.1 mm and angle tolerance 1–5°. That balances smoothness and file size.

- Verify scale in mm or inches before export.

- Run a mesh repair to fix non-manifold edges and inverted normals (your slicer or CAD usually has a tool for this).

Cautionary tale:

I once exported a large part at a coarse chord height. It looked like a low-poly sculpture. The client noticed. Since then, I pick tolerances based on the part’s smallest fillet and visible curves.

OBJ

Definition: OBJ is a mesh format that can include vertex colors, texture coordinates, and references to an MTL file for materials. It can also handle multiple shells or parts (source).

Best for:

- Color or textured prints, when the service supports zipped assets.

The STL vs OBJ decision:

If a service accepts both and the print is monochrome, I go STL.

If I need full color or decals and 3MF isn’t accepted, I choose OBJ and package it right.

Upload tip:

- ZIP the OBJ, MTL, and all textures together. Keep relative paths as exported.

- Confirm the service supports color/texture before you spend hours UV unwrapping.

Real-world lesson:

I once uploaded an OBJ without its textures. The portal showed a gray blob. I had to re-zip with the MTL and texture maps, using the exact folder structure from export. Double-checking the preview saved the job.

3MF

Definition: 3MF is a modern, compressed, XML-based package. It bundles mesh, units, colors, materials, metadata, build plate layout, and assemblies into a single file. It’s basically “STL, but grown up.”

Best for:

- Reliable metadata preservation.

- Multi-part assemblies and multi-color/material projects.

- When you want the service to see exactly what you see.

Export tips:

- Verify units are correct in the 3MF header during export.

- Include all material and color definitions.

- Re-open the 3MF in a viewer or slicer to confirm metadata sticks.

If your service supports 3MF, it’s often the best file format for 3D printing today. For a deep dive on why the standard exists and what it supports, the 3MF Consortium’s spec overview is an excellent resource.

Note:

3MF is not fully replacing STL yet, but it’s quickly becoming the preferred option when supported.

STEP

Definition: STEP (.step/.stp) is a CAD solid/B-Rep format that preserves exact geometry and assemblies rather than storing a faceted mesh (source). It’s the engineer’s love language.

Best for:

- High-precision mechanical parts, when the service allows STEP uploads.

- Otherwise, export a high-quality 3MF or STL.

Export tips:

- Confirm units in your CAD export settings.

- Simplify or merge tiny bodies if the service requires it.

- Remove features below the printing process’s minimum wall thickness to prevent fragile artifacts.

Personal note:

For a gearbox prototype, I always upload STEP if the portal allows it. Their tessellation matched the machine, and all critical fits came out spot-on (source). If they don’t take STEP, I export a fine 3MF and call it a day.

Head-to-head Comparison: STL vs OBJ

Here’s the quick mental “table” I use when choosing between STL and OBJ:

- Compatibility: STL beats OBJ for universal support.

- Color/Texture: OBJ (with MTL) wins; STL has none.

- File packaging: STL is a single file; OBJ often needs a multi-file ZIP.

- When both are accepted: For simplicity and smaller files, go STL. For detailed color or texture, go OBJ.

If you’re unsure whether colors will print, ask your service before investing time in an OBJ texture pipeline.

Decision Guide: Best File Format for 3D Printing (online services)

Here’s the straightforward decision tree I use when I’m juggling 3D printing service file formats:

- If the service supports 3MF: default to the 3MF file format for units, colors, materials, and assemblies.

- Monochrome, single-material parts: choose binary STL for maximum compatibility.

- Color/texture prints: use 3MF first; if unsupported, use OBJ + MTL + textures zipped together.

- Precision engineering parts: upload STEP if accepted; otherwise provide a fine-tessellated 3MF or STL.

- Multi-part assemblies: 3MF to preserve part grouping and names; if unsupported, follow the service’s multi-file guidelines.

This flow dovetails with the broader criteria in our guide to choosing a 3D printing service. I’ve saved so many headaches with this simple flow. It’s fast, and it aligns with how most services are evolving.

Online Service Considerations (pre-upload checklist)

When I’m preparing models, I run this checklist every time—mirroring the steps in our model-preparation guide for online printing. It keeps 3D printing service file formats from biting me later:

- Verify accepted formats and whether color/materials are supported.

- Check the units policy (mm vs inches). Prevent accidental scaling.

- Confirm maximum file size and triangle count. Use compression (3MF, ZIP) when needed.

- Ensure mesh requirements: manifold, closed surfaces, correct normals, and minimum wall thickness.

- For OBJ: zip the OBJ, MTL, and textures. Keep naming conventions and relative paths intact.

Small step, big payoff. A two-minute check can save two days of back-and-forth.

Export Settings Cheat Sheet

These are the dials I tweak before sending files. They’re format-specific and tuned for online services. They also map cleanly to the best file format for 3D printing across common scenarios.

- STL:

- Binary format.

- Chord height 0.01–0.1 mm; angle tolerance 1–5°.

- Preserve scale and confirm units.

- OBJ:

- Include the .mtl file.

- Embed or package textures in a ZIP.

- Ensure proper UV mapping.

- 3MF:

- Validate units, materials, and assemblies in the export dialog.

- Re-open the 3MF to confirm metadata is preserved.

- STEP:

- Set correct units.

- Merge bodies if required by the service.

- Remove features below the minimum printable threshold.

Those four blocks cover 95% of my exports, regardless of which 3D printing service file formats the portal lists.

Common Pitfalls to Avoid

I’ve either made these mistakes or fixed them for others:

- Units/scaling mismatches, especially with STL and OBJ.

- Missing or broken MTL/texture links for OBJ packages.

- Non-manifold meshes, inverted normals, self-intersections.

- Overly coarse tessellation causing visible faceting (our 3D printer resolution guide explains why this shows up).

- Excessively dense meshes creating huge files and slow uploads.

Being mindful of these keeps your 3D printing service file formats friction-free for the service team and for you.

Conclusion

If you’ve been burned by uploads before, you’re not alone. I learned the hard way and then built a system. Here’s the bottom line among 3D printing service file formats:

- 3MF is the top choice when supported. It carries units, colors, materials, and assemblies with less ambiguity.

- STL remains the universal fallback. It’s simple and dependable for single-material parts.

- OBJ is best for color and texture if 3MF isn’t available, as long as you ZIP all assets and keep paths consistent.

- STEP is ideal for precision mechanical parts when accepted; otherwise, export a fine 3MF or STL.

Before you export, double-check your service’s file format policy, units, and packaging guidelines. Two minutes here will prevent days of rework. And if you only remember one thing from this whole piece, let it be this: choose the best file format for 3D printing based on your print’s needs—units, color, precision, and assembly—then verify everything in a viewer before you upload. Your future self (and your print) will thank you.

Frequently Asked Questions

Q: Which file format is best for a simple, single-color prototype?

A: A binary STL is usually the safest and most universally accepted choice for monochrome, single-material parts.

Q: How can I prevent scaling issues when uploading my model?

A: Always confirm the unit policy (mm vs inches) of the service and export your file with explicit units—3MF embeds units, while STL and OBJ require manual verification.

Q: What’s the safest way to submit an OBJ with textures?

A: Zip the OBJ, its MTL file, and all texture images together, keeping the original folder structure so that the service’s portal can resolve the links.

Q: When should I choose STEP over 3MF or STL?

A: Use STEP when you need exact CAD geometry and tight tolerances for mechanical parts and the service explicitly accepts STEP uploads.

Q: Is 3MF fully replacing STL anytime soon?

A: Not immediately—STL remains universal—but 3MF adoption is accelerating because it carries units, materials, and assembly data in one file.