When exploring the realm of 3D printing, the pivotal factor influencing the final product’s quality is the 3D printer resolution. This article navigates through the intricacies of horizontal and vertical resolutions, shedding light on their impact on the end result.

Horizontal Resolution (XY Resolution):

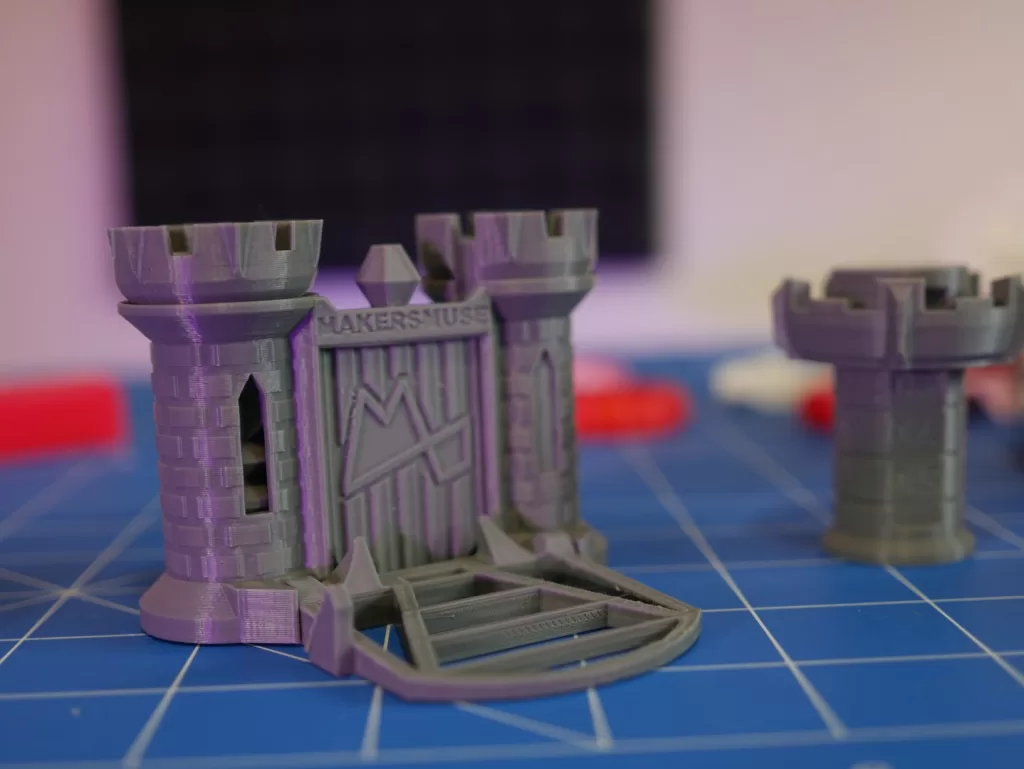

Commonly referred to as XY resolution, this dimension delineates the extruder’s minutest movement along the X and Y axes within a layer. The precision of these movements directly correlates with the level of detail in the printed object. In scenarios where precision matters, such as fine and intricate designs, a smaller horizontal resolution is imperative.

Source: Maker’s Muse

Vertical Resolution (Layer Thickness):

Also known as layer thickness or layer height, vertical resolution denotes the minimum thickness of a layer produced in a single pass. A smaller layer thickness results in a smoother surface, although it prolongs the printing process due to the increased number of layers.

Consumer FDM printers typically maintain a layer thickness between 0.12 and 0.3 mm. Remarkably, advanced models like the Ultimaker Makerbot Method X boast a vertical resolution of 0.02 mm, setting a benchmark for accuracy and detail. In contrast, SLA printers, exemplified by Anycubic and Elegoo, achieve layers as thin as 0.025 mm, elevating the detail to an even higher level.

The Influence of Printing Method:

It is crucial to recognize that a mere comparison of resolution figures holds validity only within the same technology, such as FDM with FDM. When evaluating FDM and DLP printers, distinctions emerge not only from resolution but also from the printing method and materials employed.

In FDM printing, resolution intertwines with nozzle size and the precision of the hotend’s X and Y axis movements. However, factors like bonding force between layers and weight-induced compression can compromise print quality. Notably, filament width in FDM (1.75 mm or 3 mm) does not affect XY resolution, with the printer nozzle substantially narrower.

Contrastingly, DLP 3D printers showcase superior resolution and accuracy. The optical spot of the laser or projector in the DLP process determines resolution, with less force exerted on the model during printing, resulting in a smoother surface finish. The detail achieved by DLP prints often surpasses that of FDM counterparts.

Conclusion

In the selection of a 3D printer, careful consideration of both horizontal and vertical resolutions is paramount. While DLP printers demonstrate finer detail, the overall print quality is contingent upon factors beyond resolution, encompassing the chosen printing method and materials. As such, a holistic approach ensures informed decision-making in the dynamic landscape of 3D printing.