“Insanity is doing the same thing over and over and expecting different results,” – a quote often attributed to Albert Einstein. But in the 3D printing world, is Anycubic repeating old mistakes? With the launch of the Kobra S1, a lot of eyes are on Anycubic. After the mixed reception of the Kobra 3, especially the ACE Pro multi-material system, the question is: has Anycubic really learned from its past, or is this just another 3D printer with impressive specs on paper and a history of abandonment? We’re taking a critical look at what the Kobra S1 actually offers and what you should expect before you jump on the bandwagon.

Kobra S1: The Specs vs. The Reality

Alright, let’s dive into the Kobra S1’s specs, shall we? On paper, it looks like a beast. You’ve got that enclosed CoreXY design, which is all the rage now for stability, and the advertised 600mm/s print speed. There’s also multi-filament compatibility and a 320℃ hotend, which is all very impressive. But hold your horses, folks. I’ve seen a printer or two with killer specs that totally failed to live up to the hype. This is why when new 3D printers come out, best practice is to treat it with some grain of salt.

Kobra S1 Series Tech Specs

| Printer model | Kobra S1 Combo | Kobra S1 |

| Founder’s price | $549 | $379 |

| Suggested retail price | $749 | $549 |

| Multicolor printing | Supports 4- or 8-color printing | Sold separately |

| Print volume | 250*250*250mm | |

| Supporting filaments | PLA, PETG, TPU[1], ABS, ASA | |

| Print speed | 600mm/s (Max.) | |

| Recommended print speed | 300mm/s | |

| Recommended acceleration | 10000mm/s² | |

| Maximum acceleration | 20000mm/s² | |

| Machine dimension | Kobra S1: 400*410*490mm | ACE Pro: 365.94*282.84*234.5mm | |

| Package dimensions | S1C: 490*484*593mm, 25.9kg | S1: 490*484*573mm, 20.2kg | |

| Complete benchy in (according to official) | 15min | |

| Noise | 46dB (Standard mode) 44dB (Quiet mode) | |

| Nozzle temperature | 320°C | |

| Hotbed temperature | 120℃ | |

| Nozzle diameter | Standard 0.4mm Supports 0.2/0.6/0.8mm expansion | |

| Pressure advance / flow calibration | Supported | |

| Firmware solution | Kobra OS | |

| Construction | CoreXY | |

| X-axis | Linear rod | |

| Y-axis | Linear rod | |

| Z-axis | Single motor with three guide poles | |

| Extrusion form | Dual gear direct drive extrusion | |

| Hotend | Metal, quick-detachable | |

| Air filtration | Activated carbon purification | |

| Control screen | 4.3-inch capacitive touch screen | |

| Power-off resume printing | Supported | |

| Filament detection | Supported | |

| Camera | Included | |

| Video monitoring | Supported, 480P | |

| Time-lapse photography | Supported | |

| External door and top cover material | Full PC | |

| AI detection | Spaghetti recognition | |

| Skip Objects | Supported | |

Key distinctive features include:

- Easy setup with 90% of printer pre-assembled

- Integrated color management system (ACE Pro unit)

- Automatic filament loading

- Filament drying functionality

- Quick-change nozzle mechanism

- Integrated live view camera option

It’s important to ask ourselves: Are these specs truly innovative, or just a game of catch-up with brands like Bambu Lab and Prusa? It feels like every company now is pushing out these printers with the same “high speed”, “high temp” features. The reality is, many times, these high speeds are not practical. They are just there to look good on paper. If you have pushed the speed to the maximum you might start having bad quality prints, so it is important to always be careful with this. Don’t get me wrong, I love pushing the limits, but I also want quality prints, so balance is key!

Kobra 3: A Lesson in What Not to Do?

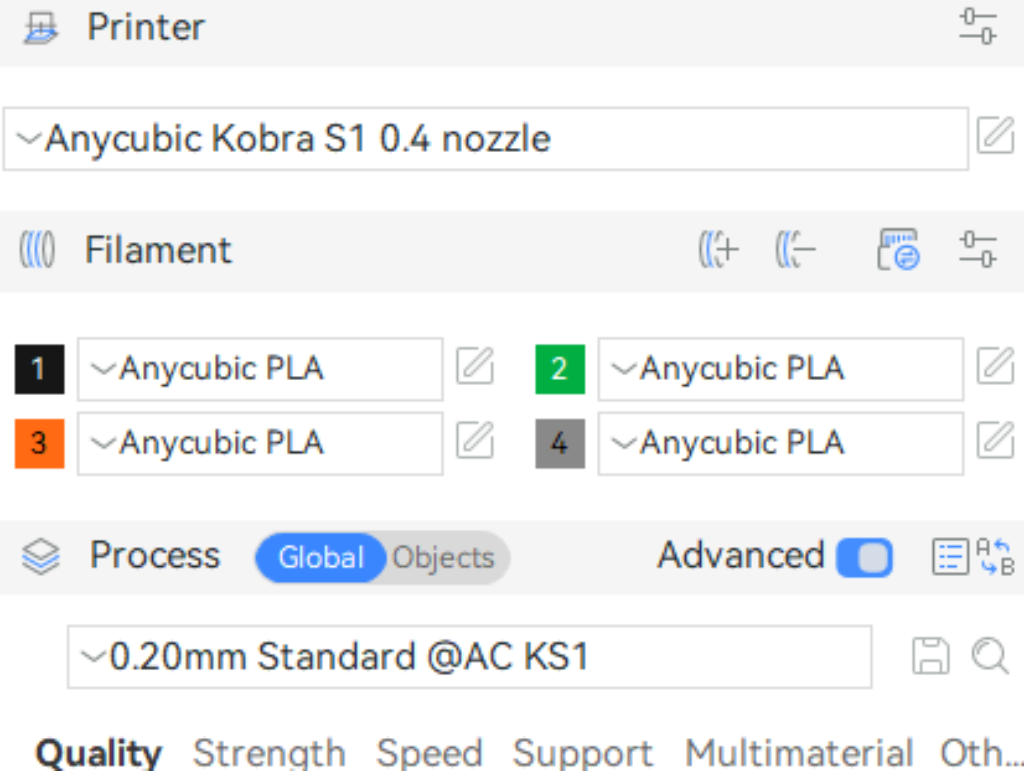

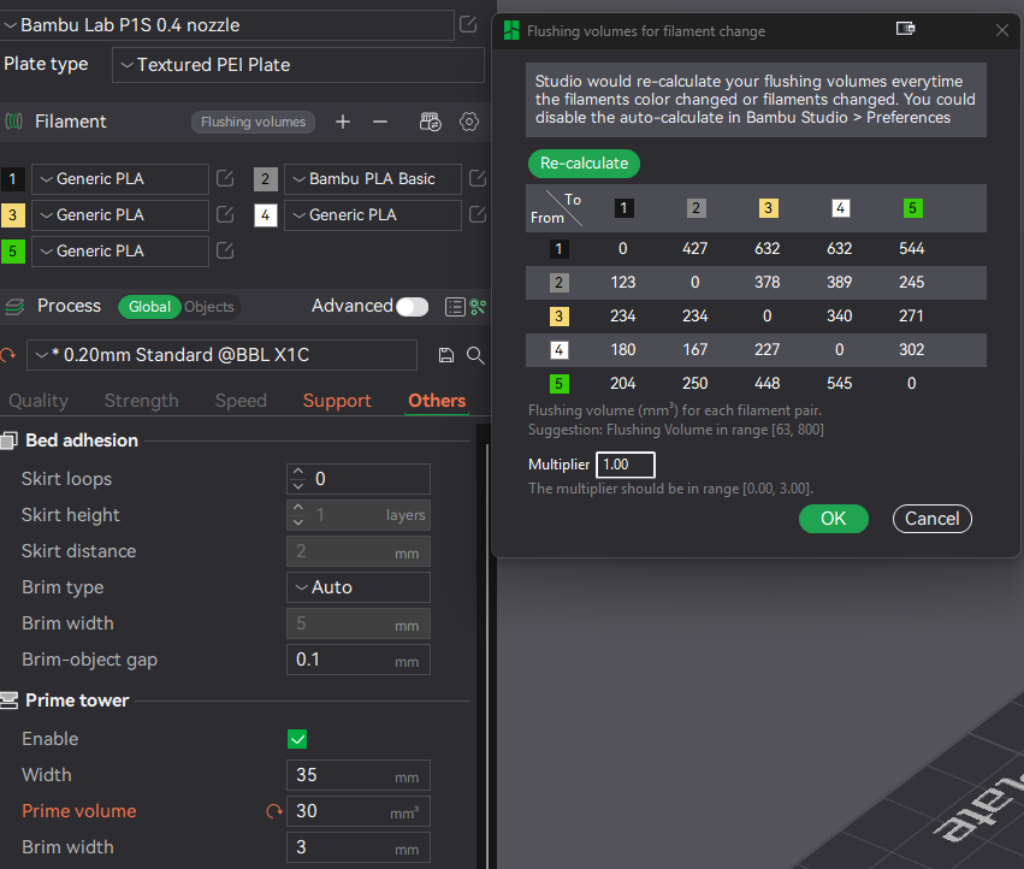

Okay, let’s talk about the Kobra 3 because honestly, that’s the elephant in the room here. It was supposed to be this multi-material contestant for the Bambu Lab printers, but it ended up being a bit of a mess for many users. The Anycubic Slicer, which comes with the Kobra 3, has been criticized for missing functionalities like the ability to tune filament purge(flushing volumes) between color changes.

There was reported no support for Bambu’s .3mf files at the launch, which means users had to paint colors themselves in the slicer. When I have installed it to check the issue, the imported Bambu’s .3mf files had the color information (version 1.3.2). Firmware updates are expected to address some of these issues, but as of the latest information, they have not been fully resolved.

There were also a lot of complaints about print quality, especially with multi-color prints. Surface quality and Z-offset were quite common, and adhesion was terrible with some printers. People were having problems with nozzle clogs, warped beds, and jamming. A small number of users have reported leakage issues with the hotend, leading to print failures. Anycubic has initiated a program for free replacement of affected quick-release hotends.

The ACE Pro accessory, which manages multiple filaments, has faced criticism for causing filament tangles, not recognizing when filament is inserted, and for its waste management during print color changes.

The Bambu Lab Comparison: Can Anycubic Compete?

So, the big question is, can the Kobra S1 compete with the likes of Bambu Lab? I am sure many of you are thinking this as well. I am sure you already saw the videos about the Bambu Lab A1 vs Anycubic Kobra 3, and Bambu seemed a lot more polished. It is user friendly, with an intuitive user interface, and the slicer is constantly being updated with new features and bug fixes. The hotend is also very well made and it’s a breeze to change the nozzles. Bambu also has a great ecosystem, with a focus on long-term support, and Anycubic, on the other hand, has a habit of abandoning old printer lines, which makes you wonder.

So, based on this past performance, is the Kobra S1 going to be a true alternative? Or will it just be another budget printer with lots of compromises? I’m not gonna lie, this is what everyone wants to know. You have to be careful when a new printer comes out and think about these past issues, and how the new printer will be any different from the last ones. There are usually some very promising claims from these manufacturers, but in practice they don’t perform up to par. So, it’s up to us, as consumers, to remain aware and informed to make a smart decision.

Kobra S1 Software and Ecosystem: Red Flags?

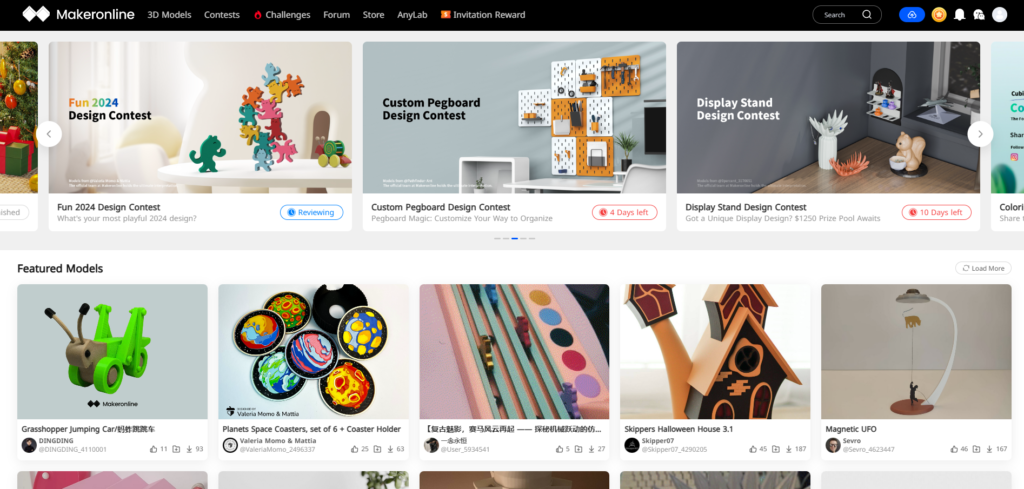

It’s interesting to see how quickly patterns emerge in new markets. 3D printing is no exception. You’ve got a few big players, and now everyone else seems to be copying what they’re doing. The problem is that when you copy, you don’t end up with a new product, you end up with the same product. And that’s what it feels like with Anycubic’s Makeronline. You could say that Makeronline is better than nothing, and that Anycubic is building their ecosystem. But it feels like they’re building it without a real point of view. They’re making a “me too” product. It’s like they’re looking at other players and just saying, “I guess we should do that too.”

The Kobra S1 is using Anycubic Slicer Next, their mobile app, and a 4.3-inch touchscreen. This is all good and dandy, but my experience with other slicers from different printer manufacturers has been far from ideal. And if we are going to be honest, the Kobra 3 was a huge letdown, and it has made a lot of us worried about the S1. Based on previous experience with Anycubic, is it a safe bet that the software will be bug-free? Or is it just going to be another mess that the community will need to fix? Because it has happened before!

The Anycubic Slicer Next is based Orca Slicer, Bambu Studio, and Prusa Slicer. They’re all open source, meaning anyone can contribute and change the source code, and they benefit from a large community. Anycubic slicer is based on Orca Slicer, so you’d think they would also make the source code available.

But it is not. It feels like Anycubic is taking the work of the open source community and making it their own. They are not giving back, which doesn’t feel right. Open source is a very good way for smaller players to catch up with bigger ones. By working together a lot can be achieved that would be impossible otherwise. But if the smaller players just take, and don’t give back, then the system doesn’t work.

Conclusion: Is the Kobra S1 the Answer, or a Repeat of the Past?

So, where does that leave us? The Kobra S1 definitely has some great potential with its impressive specs, speed, multi-material capabilities, and software enhancements. But if we have learned anything is that it does not matter how good the specifications are if they are not well implemented. And the reality is that Anycubic has had some problems in the past, especially with the Kobra 3 launch, and I believe it is important to be aware of this fact.

It’s crucial to remain critical and not get caught up in the hype. We need to be informed consumers and make our decisions based on real performance and not promises. It’s all about balance, so should you buy it? I don’t know, it will depend on you.

If you’re still trying to figure out which printer is right for you and are considering other options, especially if you’re looking for a great multi-material system, you might want to check out our guide on which Bambu Lab printer to buy in 2024. And if wall art is your thing, you can also find some ideas in our article about the top 5 printers for wall art. Is this going to be a “game changer” or just another example of the same mistakes as before? Only time will tell. It’s up to you, so think about it and make an informed purchase!