Simplified 3D printed orthotics: How 3D printing is transforming the recovery industry

Orthopedic devices, or orthoses, play a crucial role in supporting various parts of the body during recovery. From limb rehabilitation to enhancing overall stability and mobility, these devices have traditionally involved a time-consuming and expensive design process. However, the advent of 3D printing has transformed the orthotics industry, making customization faster and more cost-effective.

In the past, crafting custom orthoses was a lengthy and costly endeavor, involving multiple fitting sessions and prolonged waiting periods. The conventional approach hindered quick access to essential recovery aids. Fortunately, the integration of 3D printing techniques, including scanning and modeling, has streamlined the process, enabling the prompt production and delivery of orthoses to patients.

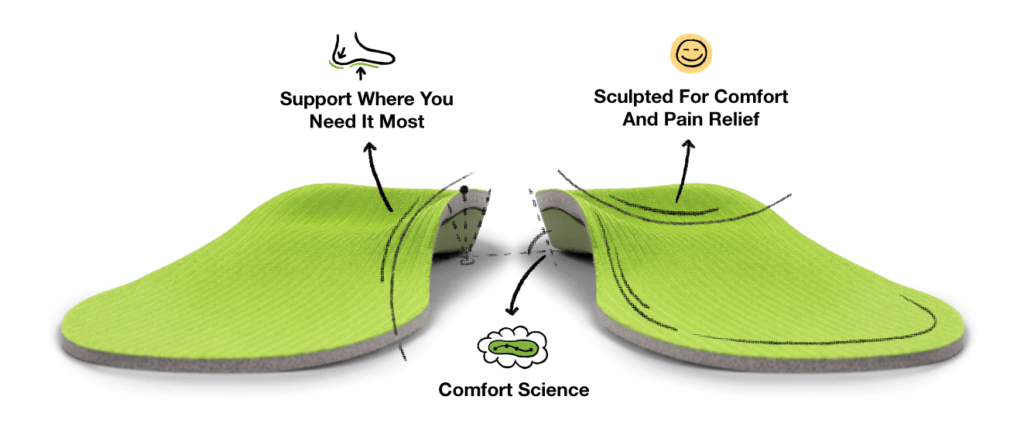

Custom comfort: the benefits of 3D printed insoles for foot pain

Discovering the benefits of 3D printed insoles for foot pain unveils a new era in custom comfort. These insoles, tailored to an individual’s foot shape and size, address conditions like heel spurs and plantar fasciitis. The 3D printing process involves data collection through 3D scanning, photographs, or manual measurements, providing accessible solutions through specialized companies or DIY tools.

Custom Fit: Three companies revolutionizing 3D printed insoles

FitMyFoot: canadian comfort

FitMyFoot a Canadian innovator, utilizes a smartphone app for personalized footwear and insoles. The 3D printed insoles, crafted from nylon plastic with a polyurethane foam coating, aim to alleviate foot conditions such as flat feet and high arches.

ME3D by Superfeet: American adaptability

ME3D by Superfeet, an American company, offers adaptability through insoles with five support zones, tailored to the user’s foot geometry.

Gensole: DIY Design

For a more hands-on approach, Gensole is a free browser-based tool for designing and 3D printing custom interior insoles for non-commercial use. The tool creates digital models optimized for 3D FDM printing with flexible filament, with the additional step of importing a 3D scanned foot model to customize the sole. The process is explained on their website.

Orthodontic appliances and brackets: Comfort and stability through 3D printing

Orthodontic appliances and braces, crucial for stability and support in various body parts, benefit significantly from 3D printing. This advanced technology allows for the creation of custom orthotics, ensuring maximum comfort and effectiveness. Augo specializes in custom trans-tibial prostheses, while Piro focuses on breathable AFO and SMO ankle and foot orthoses for children with conditions like cerebral palsy. Evoke, from OssKin, introduces the world’s first custom-fit knee orthosis, designed to enhance mobility and alleviate knee-related pain.

Revolutionizing Skull Correction with 3D Printing

Orthopedic treatment for skull deformation, known as plagiocephaly, has undergone significant advancements with 3D printing. Traditional methods involved time-consuming polymer foam milling processes for custom-made helmets. Talee and Chabloz, utilizing 3D scanning and Multi Jet Fusion manufacturing, offer efficient solutions with breathable and comfortable headgear for infants.

Comfortable Immobilization Devices with 3D Printing

Replacing traditional plaster casts, 3D printed immobilization devices enhance post-trauma and post-fracture recovery. ActivArmor provides custom immobilizers for various limbs, offering a lightweight and waterproof design for improved patient comfort. XKSoft, a Spanish solution, offers a quick and easy app-based 3D scanning solution for limb immobilizers, further expanding accessibility and convenience.