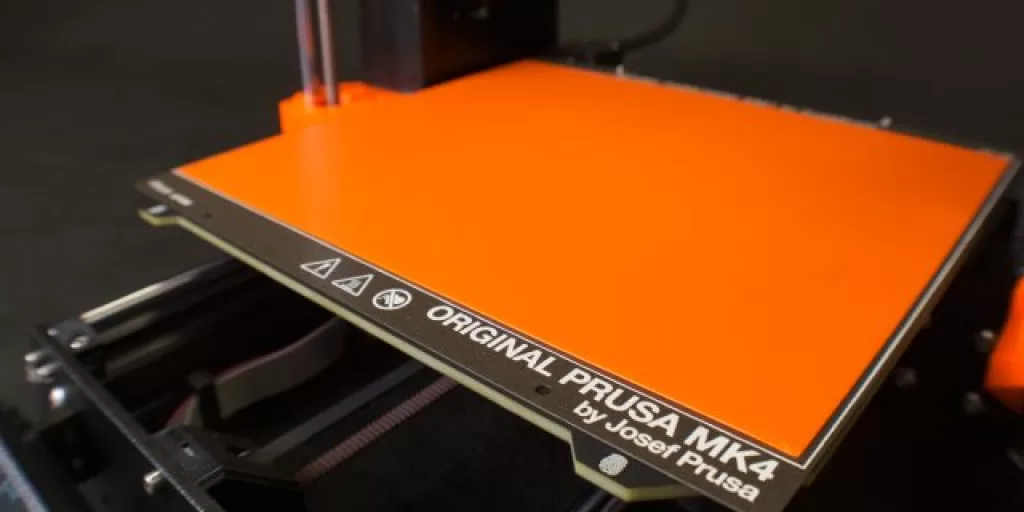

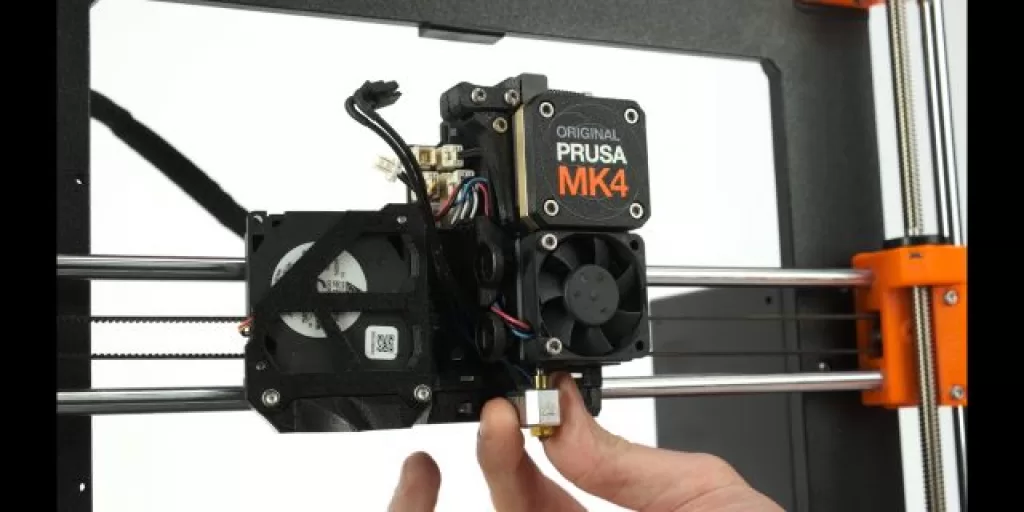

Renowned 3D printer manufacturer Prusa Research has announced the launch of its latest printer, the Original Prusa MK4. The printer features several new technologies, including the next-generation extruder (Nextruder), which provides a perfectly uniform first layer without requiring live Z adjustment. The printer also supports high-speed printing with Input Shaper and Pressure Advance, has an enhanced safety feature and is built on a 32-bit connected architecture. Other features include quick-change nozzles and integrated support for remote printing and webcams.

According to Josef Průša, founder of Prusa Research, the company already has several hundred units of the MK4 in stock and is ready to deliver them immediately. The company also plans to release upgrade kits for the MK3.5 and MK3.9 models, as well as a new Multi-Material Upgrade 3.

The MK4 is built around the same type of frame and construction as the MK3 line, which has sold over 350,000 open-source 3D printers worldwide and won four consecutive “3D Printer of the Year” awards. However, the MK4 has upgraded more than 90% of the MK3S+ components, including a new die-cast aluminum frame, a state-of-the-art extruder and a 32-bit connected architecture.

Development of the MK4 ran in parallel with the development of the XL, and several technologies, including firmware, Nextruder and the quick-change nozzle system, were shared between the two cars. Prusa Research tested the MK4 internally for over a year, accumulating over one million hours of testing.

The MK4 is designed as a workhorse for open-source 3D printing, with long-term support, high-quality parts, easy maintenance and advanced safety features. The printer can be operated completely offline or with optional connectivity features. The company offers 24/7 technical support and hassle-free service.

The MK4 is shipping now, and upgrade kits for the MK3.5 and MK3.9 will also be available soon.